| スタイラスの調整をしたいのですが。 | ||

|

【心振れ補正方法】 ポイントファィンダーとセンタリングゲージスウィングタイプは測定器です。 お使いいただく前に補正値と繰り返し精度の確認を行ってください(これを初期設定と呼びます) 心振れが目に見えるほど大きくとも1μmで測定ができます。 | ||

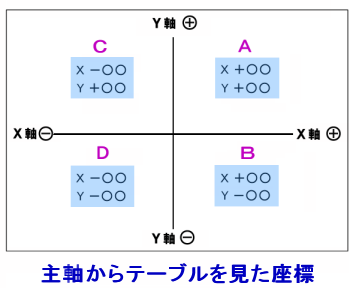

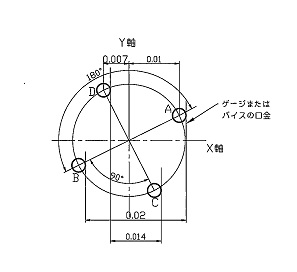

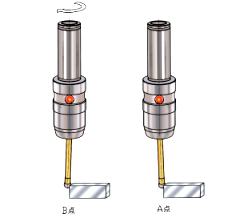

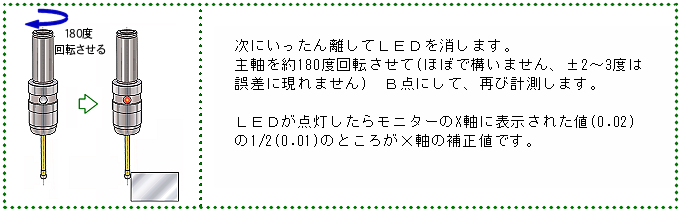

上図の原理を説明をします。 実際に心振れ量の確認をされる場合上図のようにX軸とY軸を紙に書きながら行うと分かりやすくなります。 ポイントファィンダーを主軸定位置【オリエンテーションの位置】でスタイラスの位置がA点と仮定します。

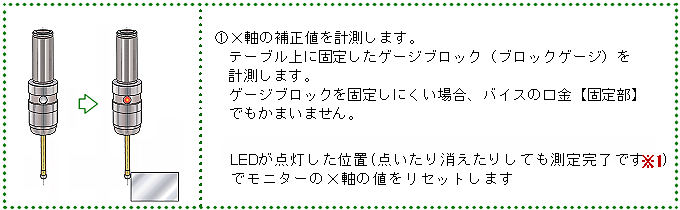

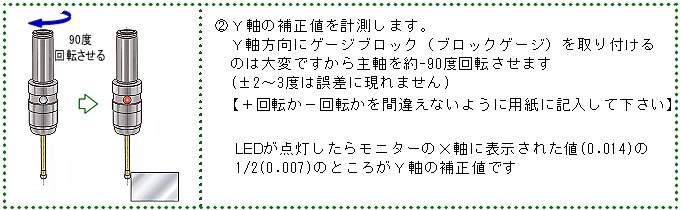

これでX軸の測定と同じ方向で測定を行えばY軸の補正値が求められます。 X軸の移動距離の1/2のところがY軸の補正値です。 注)実際の測定では必ず主軸をオリエンテーションの位置で行います。 上図の場合、X軸Y軸の値をマシニングセンターのオフセットに入力してください。 (座標が-か+かを間違わないようにしてください) 『+入力(FANUC)』『書き込み(オークマ)』機能の付いているマシニングセンターであれば、心だしのときにLEDが点灯したところでボタンを押せば 端面の座標の補正値が自動入力されます。 ※1 チャタリング現象 詳しくはこちら |

||

| この質問に関係のある商品は以下の通りです。クリックすると該当ページへジャンプします。 【ポイントファインダーシリーズ】 【センタリングゲージスウィングタイプ】 |